I have been an embedded software engineer for over 25 years, gaining extensive experience working for industry leaders such as Philips and Cochlear. At these organizations, I not only refined my programming skills but also learned valuable processes and best practices essential for developing high-quality products.

My entrepreneurial journey began during university when I started my own business and created a temperature/humidity logger, as well as a work registration system for greenhouses. This venture taught me firsthand that building a successful business involves much more than just creating a good product.

Throughout my career, I discovered my greatest satisfaction comes from collaborating closely with small, dynamic teams to bring new innovative products to life.

That’s why in recent years, I have focused on helping startups successfully bring their products to market—turning early concepts into reliable, manufacturable, and customer-ready solutions. My experience ensures that critical technical decisions support not just development, but also smooth scaling, production, and deployment when the product is ready to launch.

Beyond process optimization, I've played a significant role in growing and leading teams committed to maintaining high product quality and swiftly responding to customer needs for new features.

At heart, I remain passionate about engineering and coding, whether it's professionally or in hobby projects.

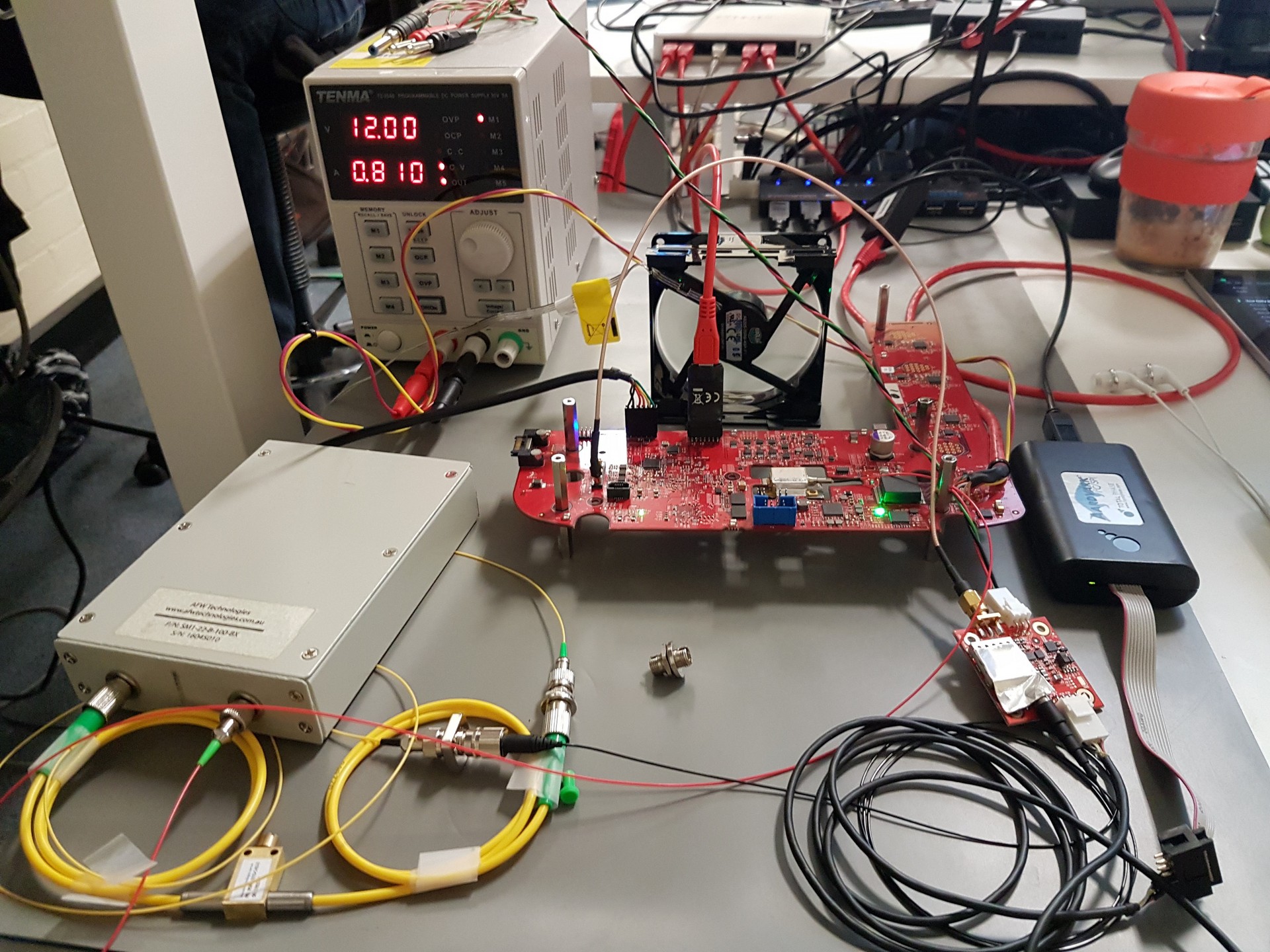

In the SiteHive Hexanode project, I transformed an early-stage noise and dust monitoring prototype—originally developed with off-the-shelf components and a Raspberry Pi—into a compact, reliable, and highly efficient MCU-based solution. This redesign significantly reduced power consumption and improved manufacturability and reliability.

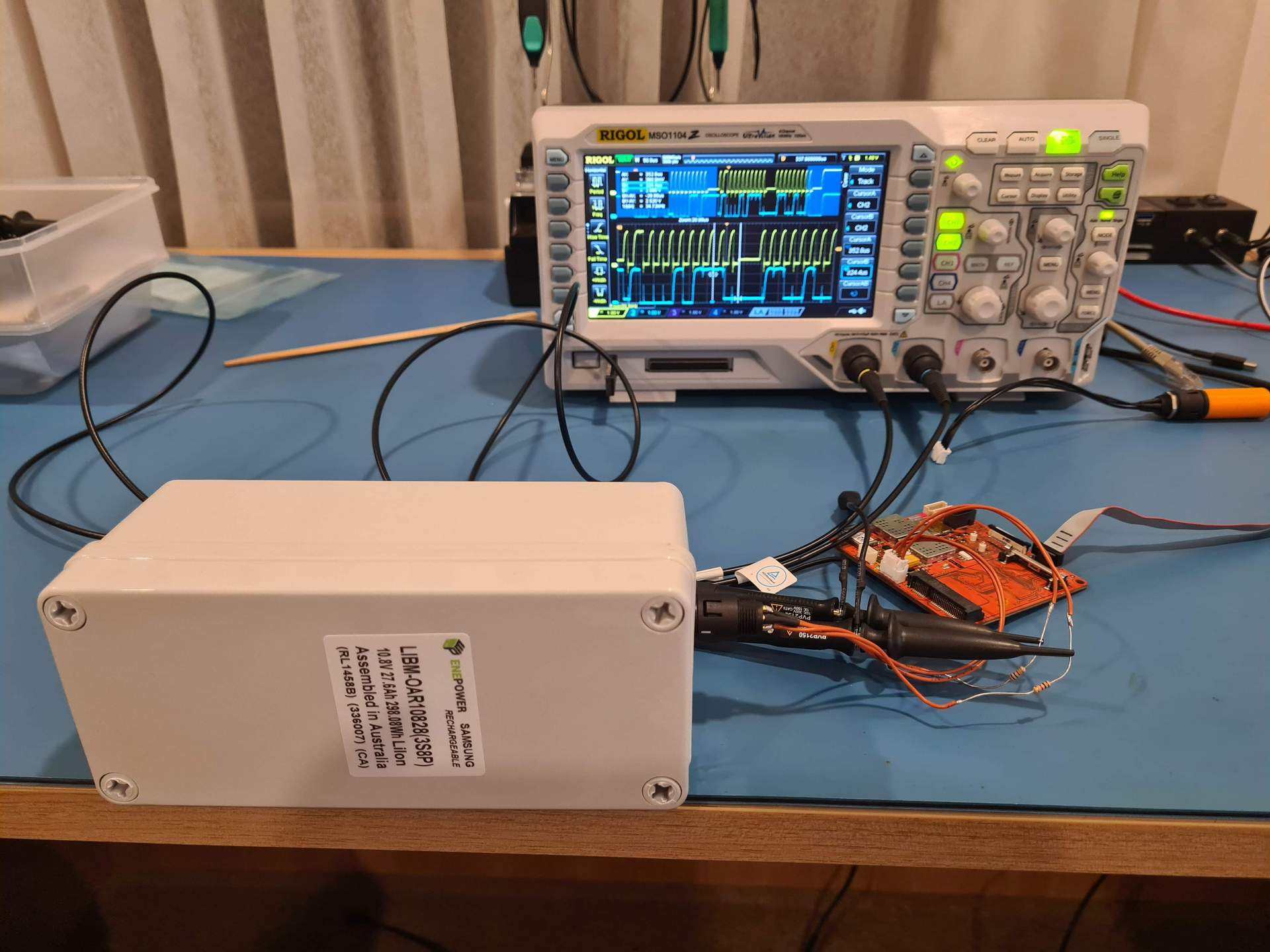

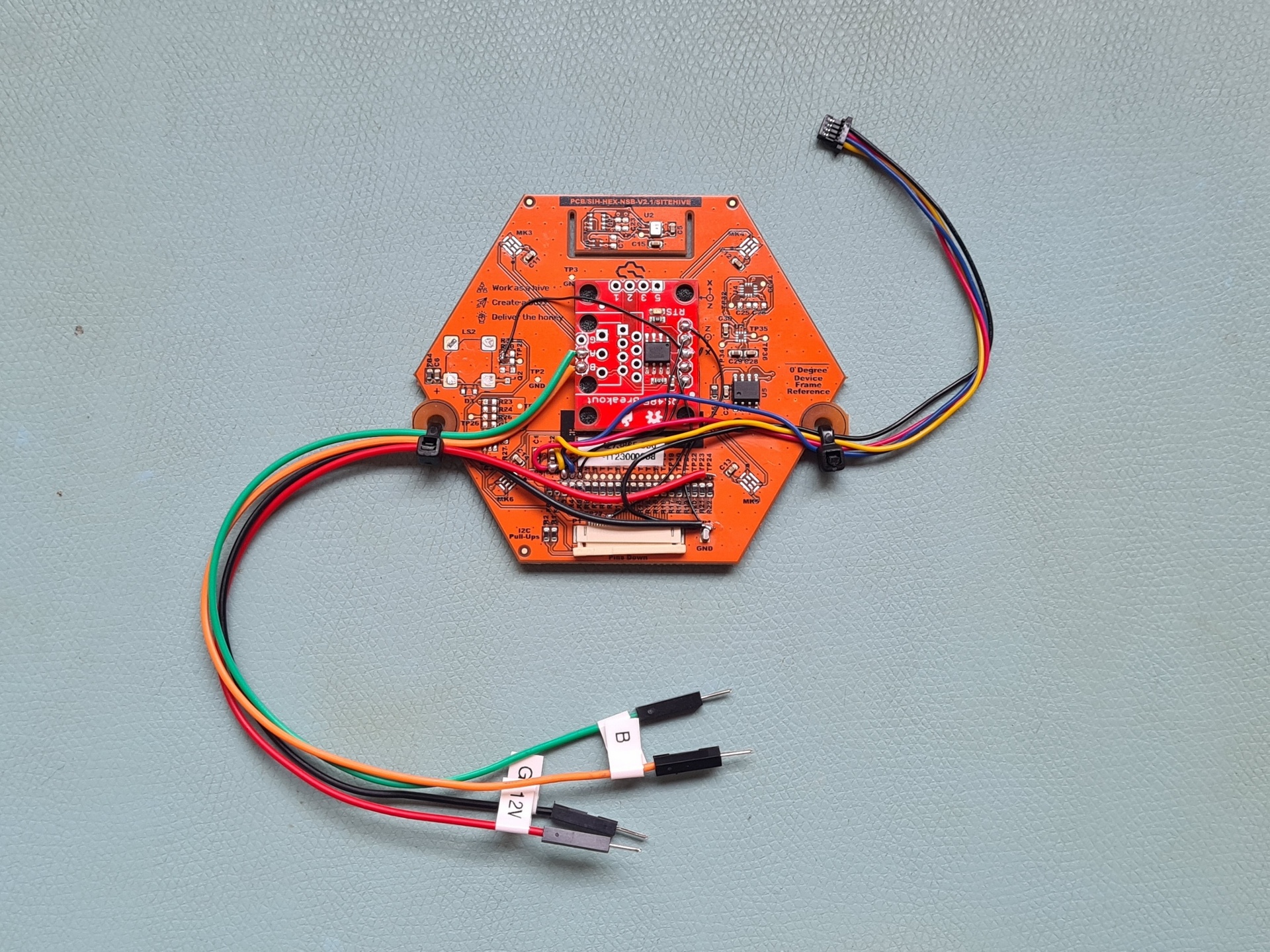

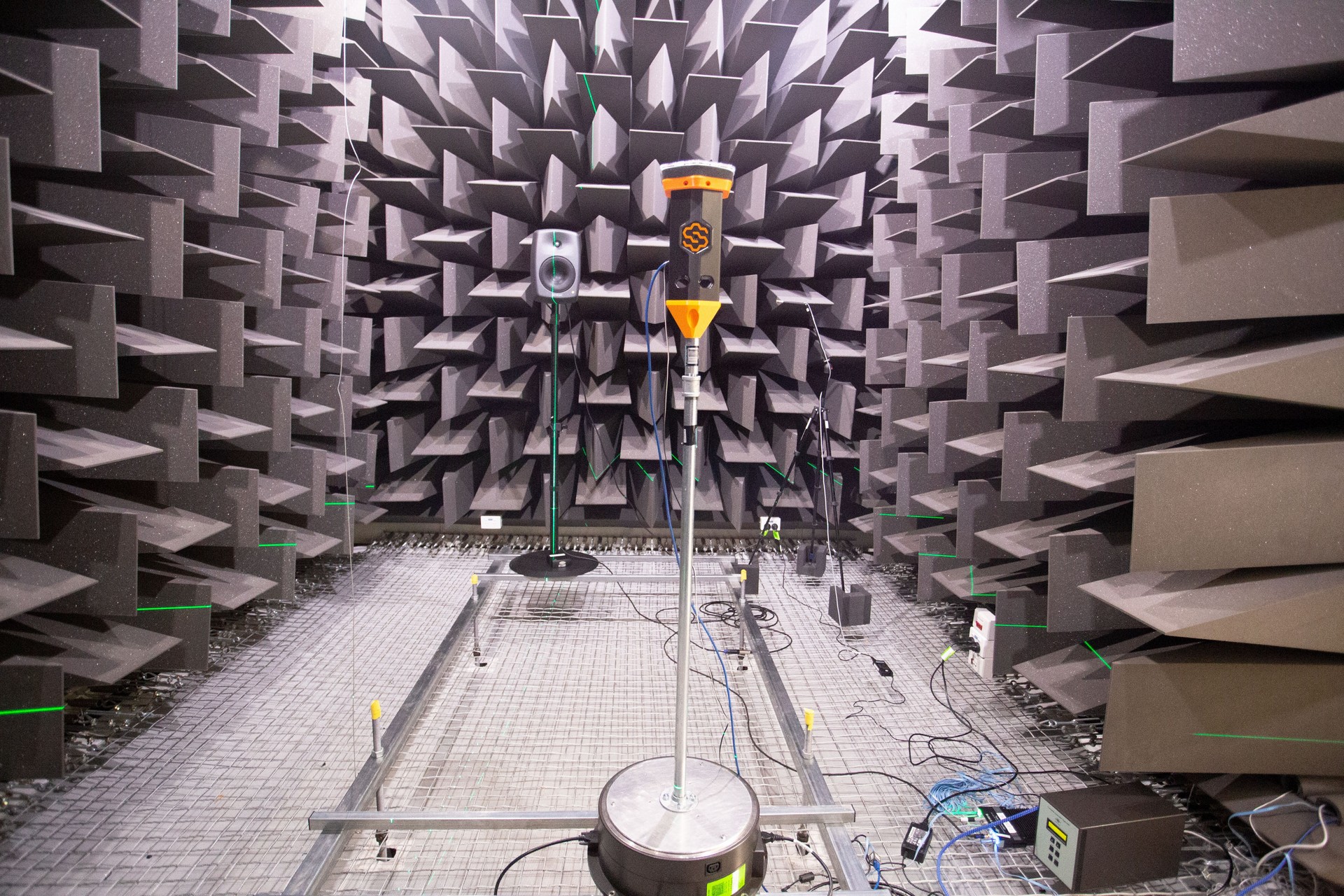

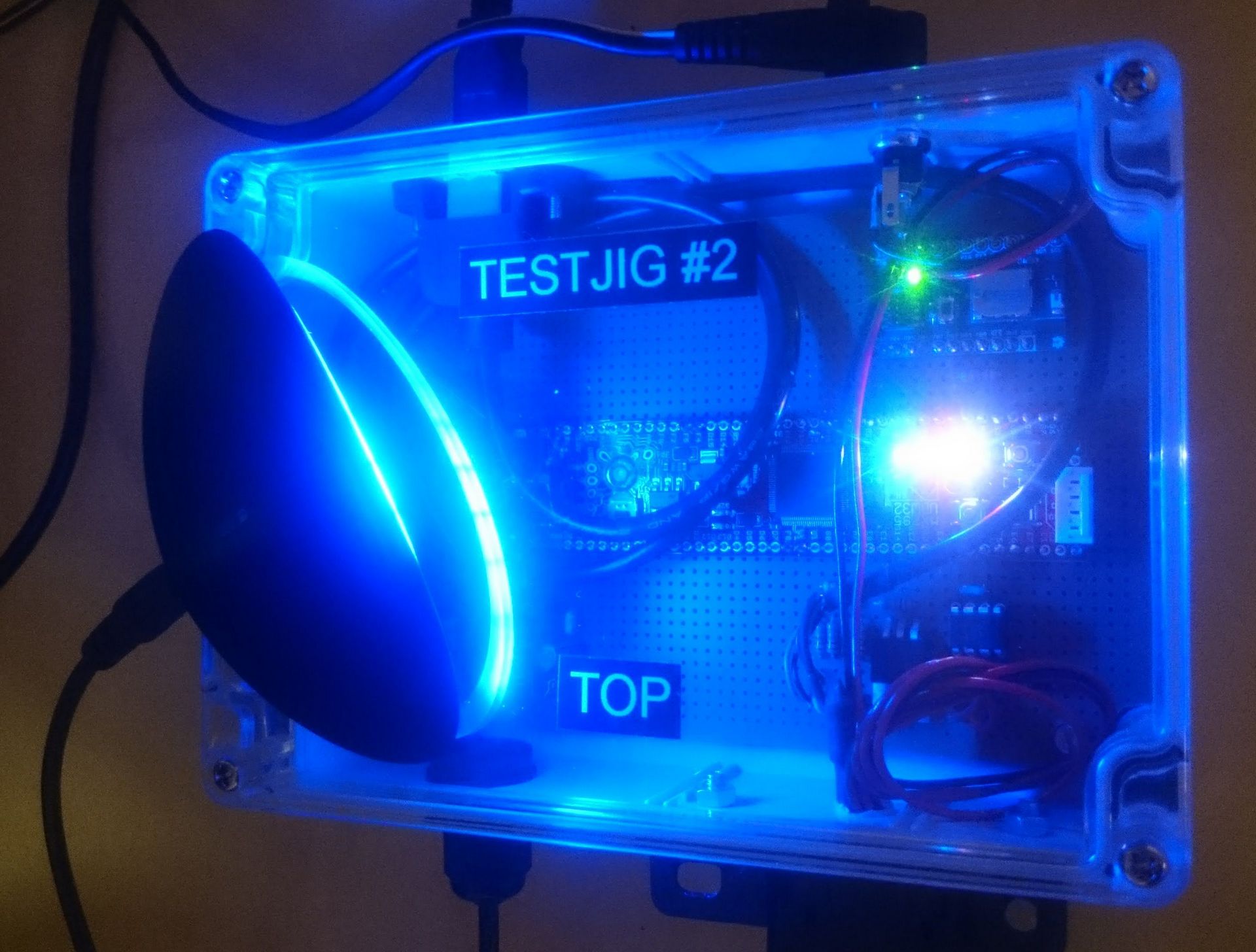

Beyond the electronics redesign, I developed 3D-printed brackets to support acoustic testing in an anechoic chamber, ensuring the accuracy and repeatability of environmental noise measurements. I also designed test jigs with 3D-printed enclosures to verify board functionality before installation into the final Hexanode product housing. These test systems, along with final acceptance tests performed on every unit before shipment, helped improve the quality and reliability.

Baraja was the first startup I joined full time. After my great initial experience helping GoFar part-time, Baraja convinced me to leave my role at Cochlear and join their team when their LiDAR system was still just an idea.

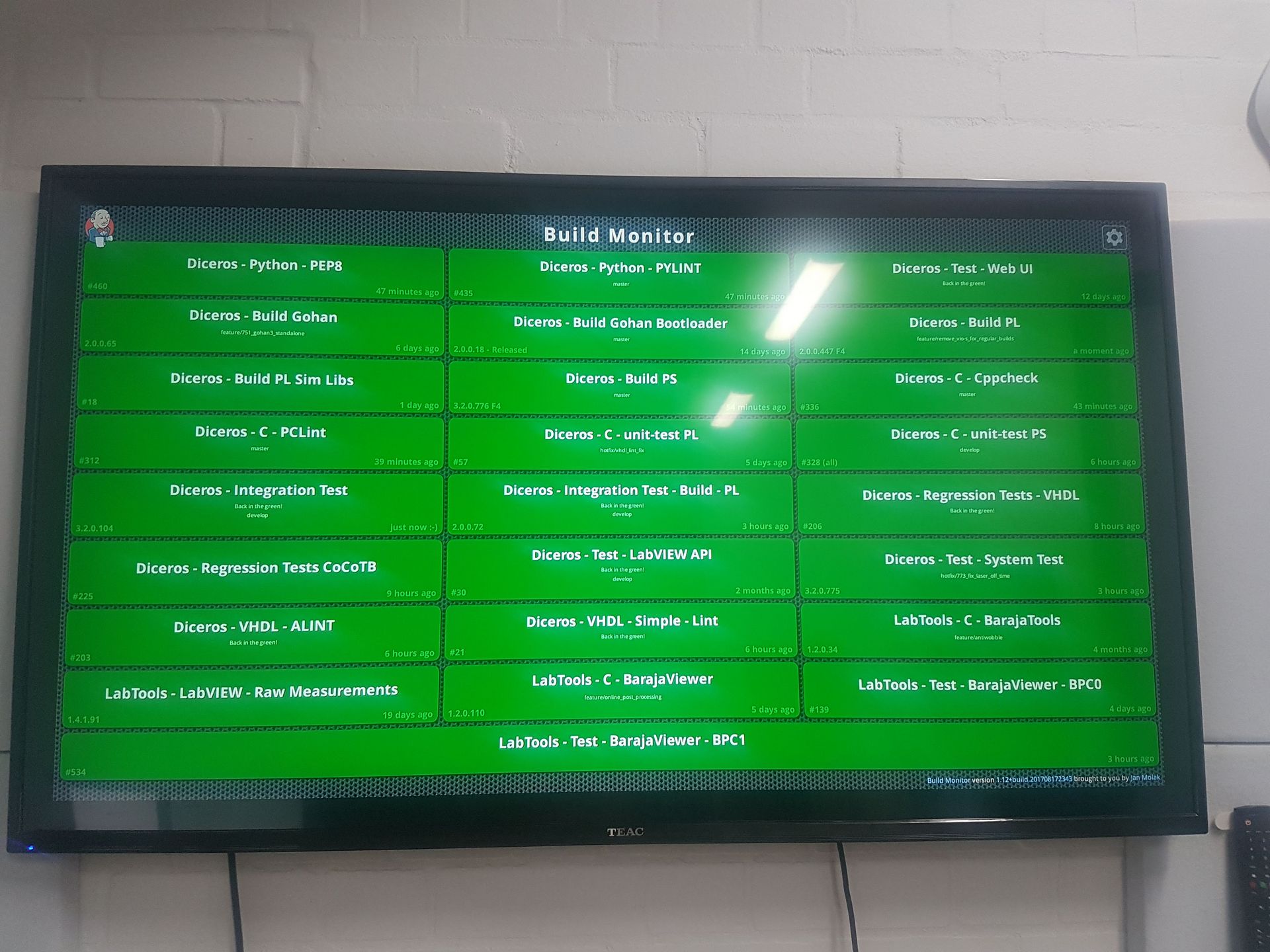

I was responsible for developing the initial firmware for the proof-of-concept. I went on to lead the team to deliver Baraja’s first working Minimum Viable Product (MVP), their LiDAR system for autonomous vehicles. As the third employee, I helped build the firmware team, growing it to eight engineers while supporting recruitment and mentoring along the way.

One of the proudest moments of my career was posting the first point cloud generated by the firmware to the internal message board with the words: “Baraja is finally a LiDAR company!!!!”

Together, our team built the core embedded software focused on real-time data processing, reliability, and scalability, enabling Baraja’s LiDAR technology to be used in automotive products.

GoFar’s award-winning automotive performance and driver feedback device started as a successful Kickstarter project, requiring robust Over-The-Air (OTA) updates to expand the range of supported vehicles over time.

I designed and developed a reliable PIC microcontroller bootloader to enable OTA firmware updates via Bluetooth Low Energy (BLE).

This solution allowed end-users to update their devices seamlessly using a mobile phone, ensuring the product could evolve and improve after deployment without requiring hardware recalls or manual servicing.

In addition to the bootloader, I developed the manufacturing test systems used to validate both the Ray and the Dongle before packaging. These test systems were built using a development board based on a PIC microcontroller from the same chip family as the product, allowing shared tooling and simplifying the test workflow. The systems connected to a PC over USB and interfaced with a custom test application written in C++, enabling the manufacturing team to run comprehensive functional tests on every unit before it was boxed and shipped.

GoFar was the first startup I supported alongside my work at Cochlear, applying my expertise to help bring their innovative product to market with a solid foundation for both firmware updates and manufacturing quality assurance.

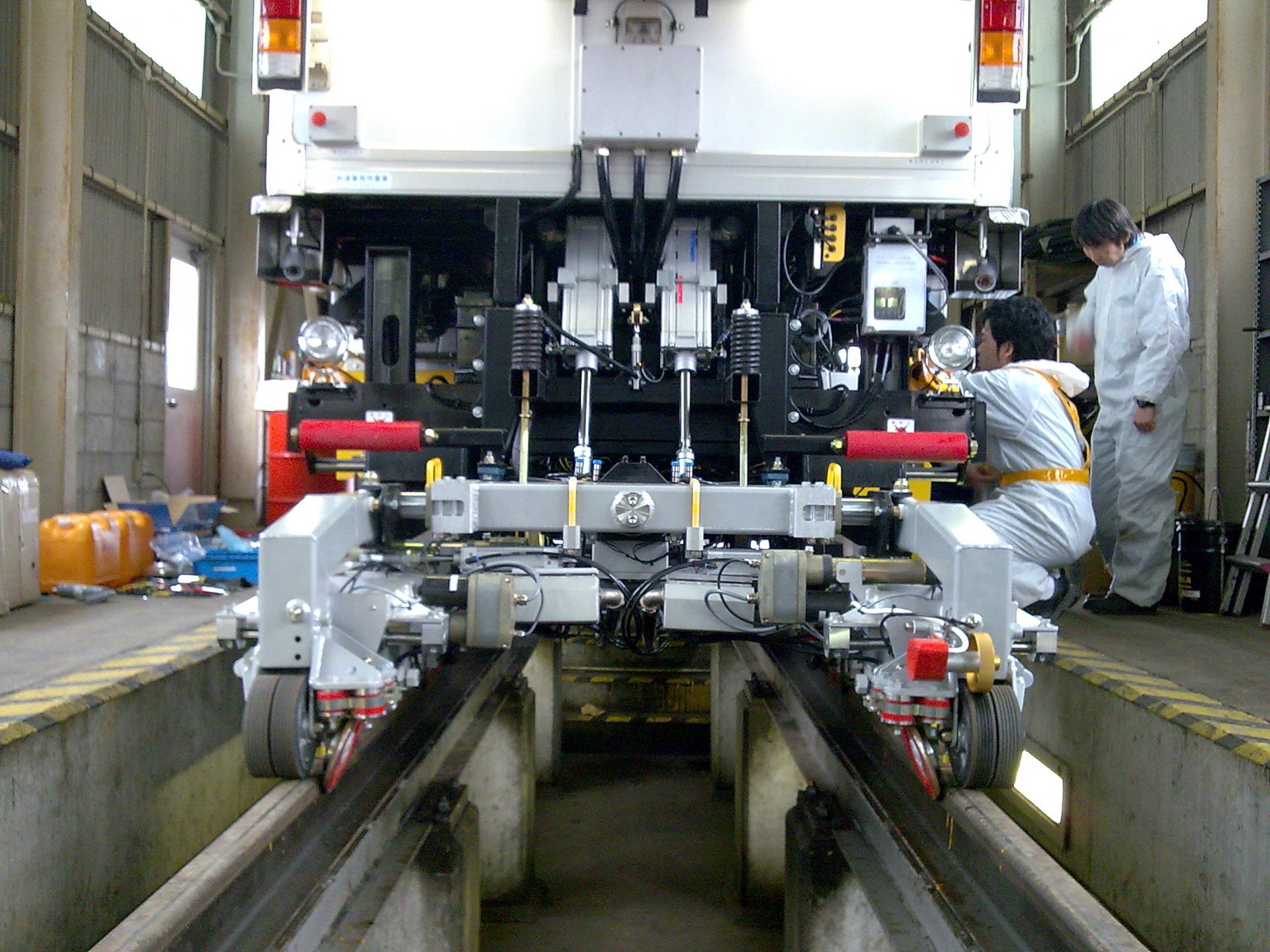

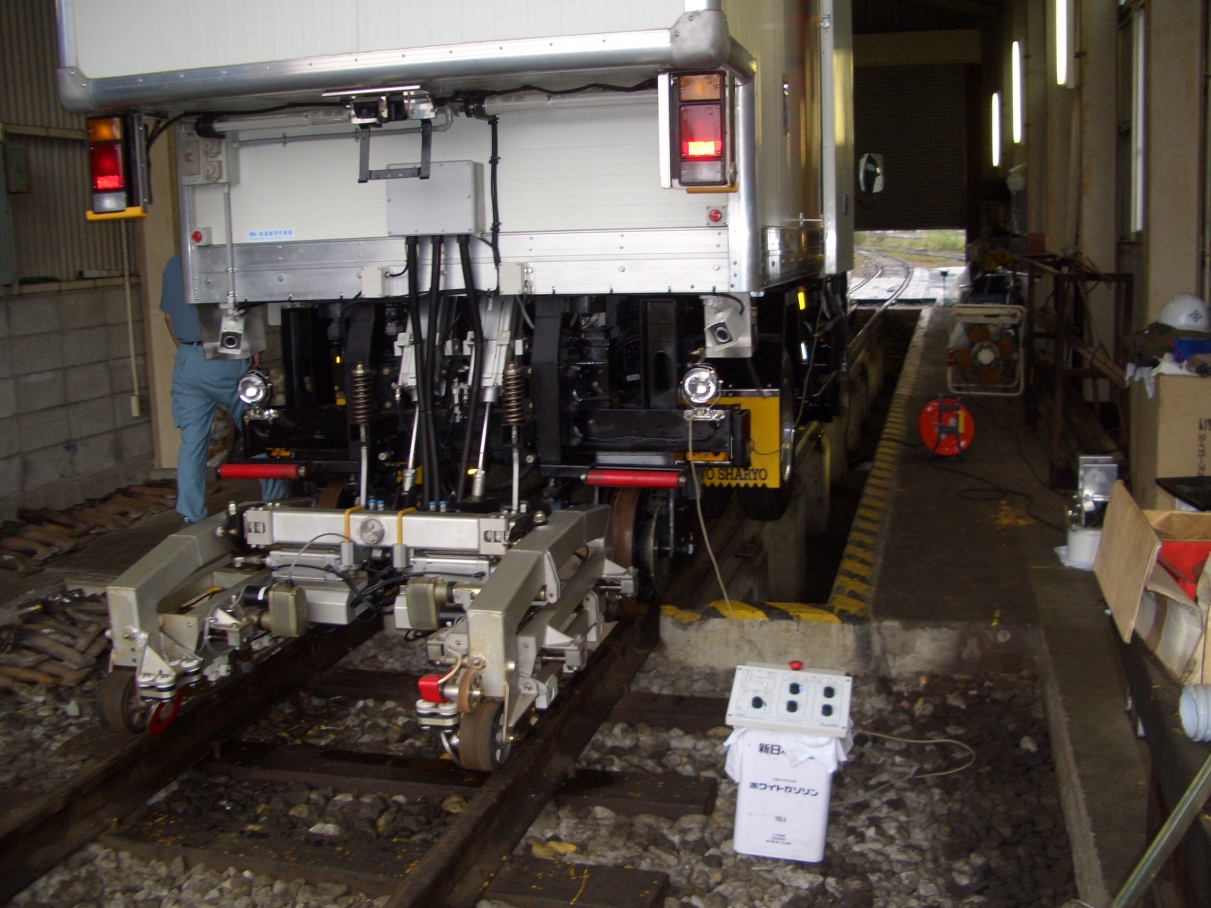

I designed and built the Test Carriage Controller used in Fairclough’s CATER ULTRAWave rail inspection system. This controller plays a critical role in the safe operation of the ultrasonic test carriage, which is responsible for detecting cracks in railway tracks using advanced ultrasonic wheelprobe technology.

The controller manages the precise raising and lowering of the test carriage, ensuring safe deployment and retraction during live rail operations. It also gives operators full control over the amount of couplant applied, which is essential for achieving reliable ultrasonic measurements. Additionally, the system allows fine adjustment of both lateral and cant positioning of the wheelprobes, ensuring they are perfectly aligned with the rail web for optimal detection performance.

Beyond the technical development, I was responsible for the installation and commissioning of the complete system on several rail inspection vehicles in Japan, ensuring successful integration and field readiness in demanding operational environments.

AJM Hendriks Electronica was a business I started while studying in The Netherlands, focused on developing practical solutions for growers in greenhouses.

The first product was a temperature and humidity data logger designed for spot check measurements in greenhouses. This allowed growers to identify hot or cold spots within their climate-controlled environments and take corrective actions to optimize plant health and energy usage.

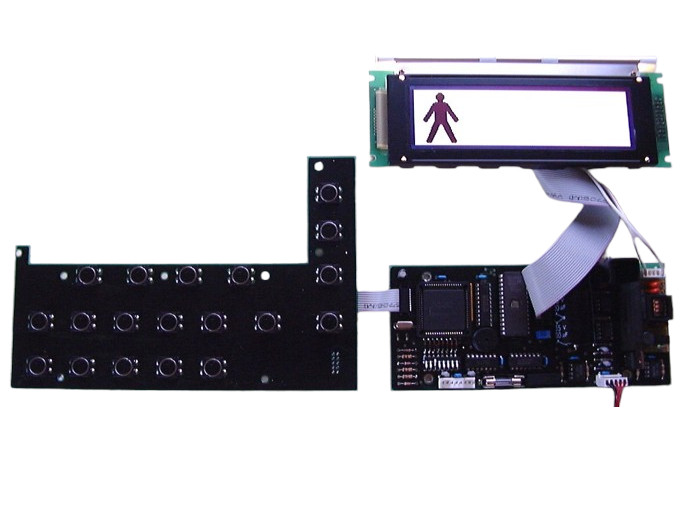

The second product was a work registration system that enabled growers to accurately track the performance of their employees based on completed work, rather than hourly estimates. This system not only streamlined payroll based on actual output but also provided quality control by allowing supervisors to monitor the consistency and accuracy of the work performed.

For both products, I also developed PC-based applications to analyze the collected data and integrate seamlessly with existing greenhouse management software, providing growers with actionable insights and operational efficiencies.

In addition to my professional work, I enjoy taking on technical challenges at home to improve everyday living.

One such project was a custom-built TV slider. Faced with the dilemma of the best viewing position being directly in front of a window, I designed and built a motorized mechanism that allows the TV to slide into the wall cavity when not in use. This solution preserves natural light and keeps the room open and uncluttered without compromising on viewing comfort.

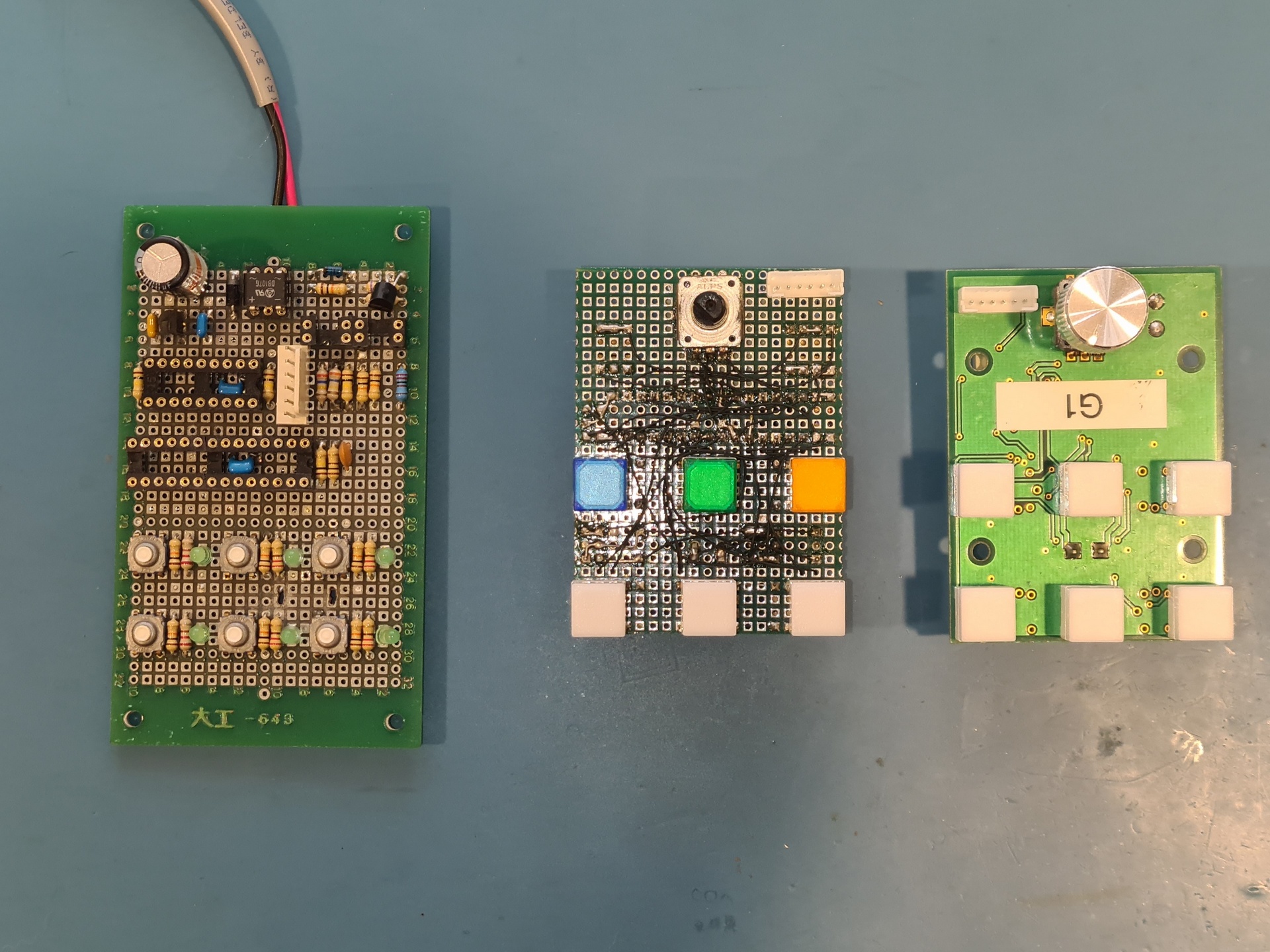

Another personal project was inspired by a childhood memory. In primary school, my teacher had a light control panel in her desk, allowing her to dim or switch the classroom lights on and off. During a full renovation of our apartment in Taiwan, I decided to bring this idea to life by developing my own DALI protocol lighting controller and custom light switches. This system gave me centralized, flexible control over the lighting throughout the apartment, blending professional-grade technology with a personal touch.

Specialized in developing reliable and efficient firmware, including bootloaders and drivers for internal and external peripherals such as CAN, SPI, I2C, modems, and WiFi chips, ensuring seamless hardware-software integration.

Expert evaluation and analysis of system architecture, schematics, and codebase, providing detailed insights and actionable recommendations to improve quality, maintainability, and scalability.

Implementation of automated build systems with automated hardware in the loop (HIL) testing, enabling consistent firmware quality, rapid iteration, and early detection of issues throughout the development lifecycle.

Design and deployment of comprehensive test systems for verifying PCB assemblies prior to integration, as well as final product testing before customer shipment, ensuring product reliability and adherence to specifications.

3D design and printing services for custom brackets, enclosures, prototypes, and other functional parts that help accelerate the development cycles or improve the manufacturing process.

Helping teams improve technical outcomes by introducing structured design reviews, coding standards, documentation practices, and quality management processes. Supporting organizations in building a solid engineering foundation that scales with the business.

I hired Xander in 2016 as one of the first employees at Baraja, and I remember how passionate he was to build a new product and build the company. He was an indispensable ally to me, eager to push the technology and take big risks, but practical enough to put the right kind of structures in our young startup. Xander left to chase more early-stage opportunities, but many of his implementations still stand today, and I'll always remember how much I loved to work with him!

We'd built a good product that customers loved but Xander showed us how to step up a gear on firmware and embedded processes and architecture, thus enabling us to be more scalable and evolve quicker.

He was a quick learner, an easy team mate to work with and had meticulous standards. We really appreciated this as firmware and our embedded product is absolutely mission critical for us and not an area we want to take chances on.

We've stayed in touch with Xander as he always gives solid, thoughtful opinions that we greatly value because they cut to the heart of the issue.

18 Cobham Avenue

Melrose Park, NSW, 2114

Australia